|

|

Sanity Check, D44 Full Floater |

Post Reply

|

Page <1 23456 19> |

| Author | ||

Anvil

Member

Joined: 07 June 2017 Location: Colorado Status: Offline Points: 326 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Mar. 2020 at 6:39pm Posted: 30 Mar. 2020 at 6:39pm |

|

One other thing, did you remove the inner housing axle oil seals? They'd be the ones just outboard of the carrier bearings. I think they'd have to be removed to 1) get lube to the wheel bearings, and 2) not build positive pressure in the axle tubes. Thoughts? |

||

|

||

Anvil

Member

Joined: 07 June 2017 Location: Colorado Status: Offline Points: 326 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Mar. 2020 at 7:15pm Posted: 30 Mar. 2020 at 7:15pm |

|

|

|

||

|

||

chasendeer

Member

Joined: 24 Feb. 2012 Location: Napa,CA Status: Offline Points: 1086 |

Post Options Post Options

Thanks(1) Thanks(1)

Quote Quote  Reply Reply

Posted: 30 Mar. 2020 at 8:15pm Posted: 30 Mar. 2020 at 8:15pm |

|

|

Just pulled my Roxor 44 apart. It has a ID of 1.265", Od of 1.625" and a depth of .14"

It looks like it would have a little left under the key way if opened up to fit a 30 spline. Jay |

||

|

||

Metcalf

Member

Sponsor Member Joined: 21 May 2009 Location: Durango, Co Status: Offline Points: 736 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Mar. 2020 at 10:37pm Posted: 30 Mar. 2020 at 10:37pm |

|

|

I don't think my axle had an inner axle seal.  My axle had PLENTY of oil at the spindle though. My axle had PLENTY of oil at the spindle though. |

||

|

42 MB that had a one night stand with a much younger 69 CJ5 and a 50s GM truck.

|

||

|

||

Metcalf

Member

Sponsor Member Joined: 21 May 2009 Location: Durango, Co Status: Offline Points: 736 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Mar. 2020 at 10:42pm Posted: 30 Mar. 2020 at 10:42pm |

|

Do you have a pic? Am I right in thinking 0.03" of wall thickness from the bottom of keyway to the ID bore? |

||

|

42 MB that had a one night stand with a much younger 69 CJ5 and a 50s GM truck.

|

||

|

||

Anvil

Member

Joined: 07 June 2017 Location: Colorado Status: Offline Points: 326 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Mar. 2020 at 10:47pm Posted: 30 Mar. 2020 at 10:47pm |

|

|

Just got off the phone with Dutchman Axles. They're helpful and patient folk. Their 30-spline flanged axles are 1.290" at the splines, then 5" or 6" past the splines, they neck up to 1.320", then 9" to 10" from the drive flange, they neck back down to 1.220".

The fee for turning the axles down to a 1.290" constant until the 1.220" dimension is $100. They don't like to do it and charge appropriately. They recommend a minimum of .025" of radial clearance between the axle shaft and the spindle. Which shouldn't be a problem since the portion of the axle within the spindle would be 1.220". On a side note, they also used to bore D44 spindles out to pass a 30-spline axle. They don't anymore. This seems to be a theme. Vague about why they don't anymore. You don't know what you don't know and what I don't know about why large bore D30/44 spindles are no longer on the market makes me uneasy. Could be lack of demand. That's cool. Could also be they broke and represent a undue risk or liability. That's uncool. They put D44s in some pretty big vehicles compared to our puny Willys. Metcalf's data set of 1 says they don't break and he wheels his rig way harder than I ever will mine. I think it'd be fine. The reason I didn't draw mine around the SET47 outer bearing is the same as Metcalf brought up. I was concerned with bearing overhang between the 1.781 bearing surface and the 1.625x16 thread and packaging it all inside the D30 hub. I had some mild concern that could also put a bending moment on the washer & nuts that maintains bearing preload and keep the hub in place in side load conditions. But I had also noted that the Dana 35 spindle I referenced earlier uses that design element and they use the same spindle nut kit as the D30/44s so I got over it. I think dual SET47s would be dandy and may address issues listed in the previous paragraph. All that said, I'm going to set this aside until my new hubs come in. There is no appreciable difference between the D44 hubs on my 1970 J4000 Gladiator (3/4-ton) truck and the Dana 30 hubs. Same Crown part number too: S437 |

||

|

||

Metcalf

Member

Sponsor Member Joined: 21 May 2009 Location: Durango, Co Status: Offline Points: 736 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Mar. 2020 at 10:55pm Posted: 30 Mar. 2020 at 10:55pm |

|

Yup, I had to pay extra to have the axles turned down to spline major for the entire length of the shaft. I would have honestly rather had them go down to spline minor, but they didn't seem interesting in that when I asked. I think they charged me $60 back when. If the axle was turned to spline minor the spindle could be VERY close to spline major. All it would need is just enough to pass the splines. Then the step down in diameter to spline minor on the rest of the shaft could provide running clearance. This could let us keep more meat in the spindle. |

||

|

42 MB that had a one night stand with a much younger 69 CJ5 and a 50s GM truck.

|

||

|

||

Anvil

Member

Joined: 07 June 2017 Location: Colorado Status: Offline Points: 326 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Mar. 2020 at 10:56pm Posted: 30 Mar. 2020 at 10:56pm |

|

So the D44 on my CJ3A has axle seals just outboard of the differential carrier bearings. They keep the gear oil in the pumpkin and out of the axle tubes. The outer axle bearings are greased and have a zerk fitting just inside the flange. The axle tubes are presumably supposed to be dry. Mine was filled 70-years of sludge, mud, rust, and broken promises.

Edited by Anvil - 30 Mar. 2020 at 11:00pm |

||

|

||

Anvil

Member

Joined: 07 June 2017 Location: Colorado Status: Offline Points: 326 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Mar. 2020 at 11:10pm Posted: 30 Mar. 2020 at 11:10pm |

|

Agreed. They told me I'd be better off boring the spindle to 1.340 rather than 1.320. Only so much real estate without going up to a bigger spindle nut and that might be the best answer. With some cursory searching, I couldn't find a standard spindle nut/washer between the D44 and the D60. That's a big ass jump between those two. Seems like there ought to be a 1.75" spindle nut kit out there. It's ridiculous, but a fellow could always make his own...it's just a small step from making your own spindles. It would package fine if you made them in the round style like late model spindle nuts. All I wanted was a Pepsi.

|

||

|

||

chasendeer

Member

Joined: 24 Feb. 2012 Location: Napa,CA Status: Offline Points: 1086 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 30 Mar. 2020 at 11:33pm Posted: 30 Mar. 2020 at 11:33pm |

|

|

I will try t get it tonight and load them here

Jay |

||

|

||

Bob W

Member

Sponsor Member x 4 Joined: 08 Aug. 2005 Location: Monticello, NY Status: Offline Points: 1691 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar. 2020 at 12:32am Posted: 31 Mar. 2020 at 12:32am |

|

I have never seen that arrangement on a CJ-3A.

|

||

|

||

Anvil

Member

Joined: 07 June 2017 Location: Colorado Status: Offline Points: 326 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar. 2020 at 2:08am Posted: 31 Mar. 2020 at 2:08am |

|

You know what? I haven't either, not even on the one I have. I went back down and looked at it and you're right. I was thinking about the oil seal behind the outboard axle bearing. Probably confused it in my pea brain because I knocked the short side out using an aluminum bar I inserted into the carrier housing. Thanks for the catch.

|

||

|

||

Anvil

Member

Joined: 07 June 2017 Location: Colorado Status: Offline Points: 326 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar. 2020 at 4:18am Posted: 31 Mar. 2020 at 4:18am |

|

|

Once you jump the mental hurdle that you could just make your own spindle nut & washer, it gets a lot simpler. This may exist already on a shelf somewhere but I couldn't find it.

Just make the entire snout of the spindle 1.781". Custom thread it for 1.781" x 16 to the nominal .9" dimension. The nut with plenty of wall and in the round body configuration has plenty of room within the hub body. Doing it this way gives you a .193 wall thickness between a 1.320 bore and the minor diameter of the thread. Quick sketch of the nut with a 1.781 x 16 internal thread:  Edited by Anvil - 31 Mar. 2020 at 4:21am |

||

|

||

jpet

Moderator Group

Sponsor Member x 5 Joined: 30 Apr. 2008 Location: Ramsey, IL Status: Offline Points: 11173 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar. 2020 at 10:36am Posted: 31 Mar. 2020 at 10:36am |

|

|

I can make spindles and nuts. I wouldn’t have a way of stamping out the washer or locking plate. That would have to be farmed out.

Edited by jpet - 31 Mar. 2020 at 10:38am |

||

|

CJ2A #29110 "General Willys"

MB #204827 "BAM BAM" "We do what we can, and we try what we can't" |

||

|

||

Anvil

Member

Joined: 07 June 2017 Location: Colorado Status: Offline Points: 326 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar. 2020 at 4:37pm Posted: 31 Mar. 2020 at 4:37pm |

|

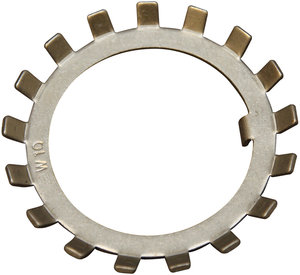

Still looking for an off the shelf tab washer but did find a spindle nut lock washer:  |

||

|

||

Anvil

Member

Joined: 07 June 2017 Location: Colorado Status: Offline Points: 326 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar. 2020 at 5:42pm Posted: 31 Mar. 2020 at 5:42pm |

|

|

Couldn't find a internal tab washer that'd work. I'm betting they're out there, just beyond my Google Fu.

Sketch of a substitute. Run fast and easy on a lathe with live tooling. Mill the ID profile otherwise.  |

||

|

||

chasendeer

Member

Joined: 24 Feb. 2012 Location: Napa,CA Status: Offline Points: 1086 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar. 2020 at 5:47pm Posted: 31 Mar. 2020 at 5:47pm |

|

|

You guys have skills!!! I sketch on napkins with my daughters crayons!!

Jay

|

||

|

||

Anvil

Member

Joined: 07 June 2017 Location: Colorado Status: Offline Points: 326 |

Post Options Post Options

Thanks(0) Thanks(0)

Quote Quote  Reply Reply

Posted: 31 Mar. 2020 at 7:39pm Posted: 31 Mar. 2020 at 7:39pm |

|

No shame in that. I can't speak for Jpet but I have done some of my best work on napkins. Everybody these days are all about ProE and Solidworks and all that, and while I have those tools, if I don't have to go beyond pen & paper, I don't. I use Solidworks for assemblies and Mastercam for more complex stuff I'm going to CNC, but for simple stuff, I'd just program it at the control or run it by hand. My Dad was a machinist for over 50-years and as a kid if I couldn't make something from one of his sketches, he'd bat me upside the head and say something along the lines of, "Do you want to go to art school or be a machinist? Go make parts!" Usually followed by, "If I got to do it, what do I need you for?" He's been dead a long time now and I still laugh about that stuff. I keep his picture on his old toolbox by the lathe so he can look over my shoulder. I hear him talking to me all the time.  |

||

|

||

Post Reply

|

Page <1 23456 19> |

| Tweet |

| Forum Jump | Forum Permissions  You cannot post new topics in this forum You cannot reply to topics in this forum You cannot delete your posts in this forum You cannot edit your posts in this forum You cannot create polls in this forum You cannot vote in polls in this forum |